Cost-Effective Mining Machine Repair Solutions in Mexico

Mexico, a land of vibrant culture and burgeoning technological adoption, is rapidly becoming a hotspot for cryptocurrency mining. The allure is clear: relatively affordable electricity costs compared to other nations, coupled with increasing awareness of digital assets, creates a fertile ground for miners. However, the harsh reality of mining inevitably surfaces – the dreaded hardware failure. Mining machines, relentless workhorses churning through algorithms day and night, are prone to breakdowns. This necessitates accessible and, crucially, cost-effective repair solutions. Navigating the landscape of Mexican mining machine repair requires a strategic approach, understanding local nuances, and leveraging available resources.

The first step is acknowledging the specific challenges faced in Mexico. Import duties and logistical complexities can significantly inflate the cost of replacement parts. Shipping times can also be lengthy, resulting in downtime and lost revenue. Therefore, relying solely on overseas suppliers for repairs is often impractical. Instead, focusing on local expertise is paramount. Identifying skilled technicians within Mexico who possess the knowledge to diagnose and repair various types of mining hardware is crucial. These individuals can be found through online forums, mining communities, or referrals from existing mining operations. Verifying their credentials and experience is essential before entrusting them with valuable equipment.

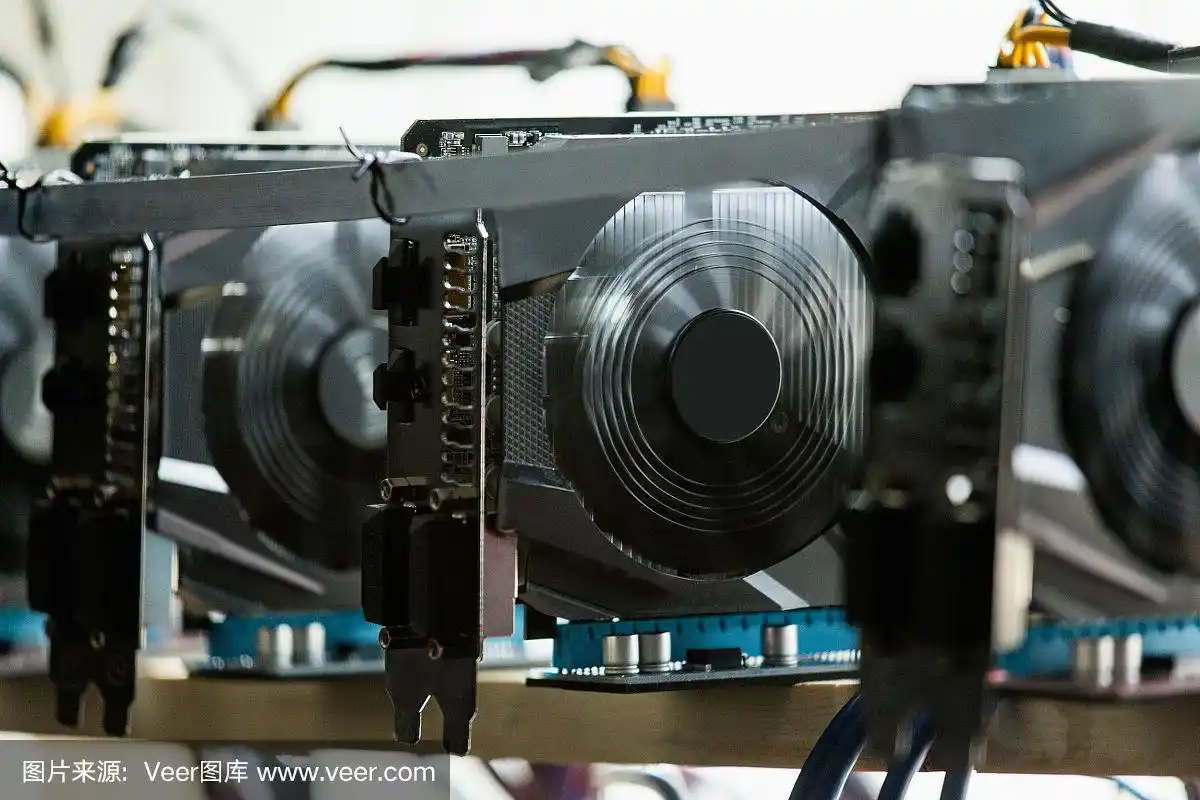

Another significant factor is the type of mining being conducted. Are we talking about Bitcoin (BTC) ASICs, Ethereum (ETH) GPU rigs, or perhaps even Dogecoin (DOGE) mining setups? Each type of hardware requires specialized knowledge and tools for effective repair. Bitcoin ASICs, for example, often require micro-soldering skills and familiarity with specific chipsets. GPU rigs, on the other hand, may suffer from overheating issues, requiring expertise in cooling solutions and thermal management. Understanding the specific hardware requirements is essential for selecting the right repair service.

Preventive maintenance is undoubtedly the most cost-effective repair solution. Implementing a proactive maintenance schedule can significantly reduce the likelihood of unexpected breakdowns. This includes regular cleaning to remove dust and debris, monitoring operating temperatures to prevent overheating, and ensuring adequate ventilation. Furthermore, regularly inspecting cables and connectors for damage can prevent electrical issues. Investing in high-quality power supplies and surge protectors is also a wise precaution. A small investment in preventive maintenance can save significant costs associated with repairs and downtime in the long run.

Exploring alternative sourcing options for replacement parts can also lead to cost savings. Instead of relying solely on official manufacturers, consider exploring the secondary market for used or refurbished parts. Websites like eBay or specialized mining hardware marketplaces can offer significant discounts on components. However, it’s crucial to exercise caution and thoroughly vet sellers to ensure the quality and authenticity of the parts. Testing the parts thoroughly before deployment is also highly recommended.

Warranty considerations should not be overlooked. Many mining machines come with a manufacturer’s warranty that covers certain types of repairs. Before attempting any repairs, it’s essential to check the warranty terms and conditions to determine if the issue is covered. Attempting unauthorized repairs may void the warranty, so it’s crucial to adhere to the manufacturer’s guidelines. Contacting the manufacturer or authorized service providers for warranty repairs is often the most cost-effective option.

Beyond individual repairs, consider the broader context of mining farm operations. For large-scale mining operations, establishing an in-house repair facility may be a viable option. This allows for greater control over the repair process, reduces downtime, and eliminates the need to rely on external service providers. Investing in training for in-house technicians and equipping them with the necessary tools and equipment is essential for the success of an in-house repair facility.

In conclusion, navigating the landscape of cost-effective mining machine repair solutions in Mexico requires a multi-faceted approach. Prioritizing local expertise, implementing preventive maintenance schedules, exploring alternative sourcing options for replacement parts, understanding warranty considerations, and considering the feasibility of in-house repair facilities are all crucial elements of a successful strategy. By adopting a proactive and strategic approach, miners in Mexico can minimize downtime, reduce repair costs, and maximize the profitability of their operations. The future of cryptocurrency mining in Mexico is bright, but only those who are prepared to address the challenges of hardware maintenance will truly thrive.

In Mexico, cost-effective mining machine repairs blend innovative local tweaks with global tech, yielding surprising durability and savings. This approach unexpectedly boosts sustainability, potentially reshaping the industry’s competitive edge.